Welcome to the Be Cu Manufacturing Company, Inc. website. We are a precision metal stamping company located in Scotch Plains, NJ. Be-Cu produces a wide variety of precision metal stampings and value added secondary processes such as plating, heat treating and assembly.

Be Cu provides its customers with total service - from prototype engineering assistance to finishing operations. We are committed to providing our internal and external customers with products that consistently meet or exceed their demand.

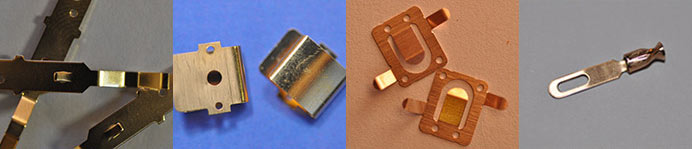

Metal Stamping

Be Cu is a full service contract manufacturer of precision metal stampings and assemblies for the aerospace, aircraft, medical, electronic, automotive, military, defense, telecommunications, and rail industries. We produce items such as:

• Contacts

• Springs

• Washers

• Clips

• Shims

• Contacts

• Springs

• Washers

• Clips

• Shims

Electroplating

Electroplating is an integral and important part of our manufacturing process.

Be Cu handles plating competently and creatively, in keeping with it's overall emphasis on quality. That well-earned reputation translates into important benefits for your company

• Gold Plating Services

• Silver plating

• Tin plating

• Copper plating

• Nickel plating

• Electroless Nickel Plating

Be Cu handles plating competently and creatively, in keeping with it's overall emphasis on quality. That well-earned reputation translates into important benefits for your company

• Gold Plating Services

• Silver plating

• Tin plating

• Copper plating

• Nickel plating

• Electroless Nickel Plating

Wire EDM

Our EDM

allows us to give you:

• Complex Geometry

• Fast Turnaround

• Work in all Metals

• Prototypes to Production

• Precision Tool & Die Components

• Complex Geometry

• Fast Turnaround

• Work in all Metals

• Prototypes to Production

• Precision Tool & Die Components

Assembly

Instead of sending components to various subcontractors for specialized steps, you can reduce lead time, maintain tighter control and superior quality through a single source.

• Soldering

• Riveting and staking

• Screwing and bolting

• Ultrasonic plastic welding

• Soldering

• Riveting and staking

• Screwing and bolting

• Ultrasonic plastic welding